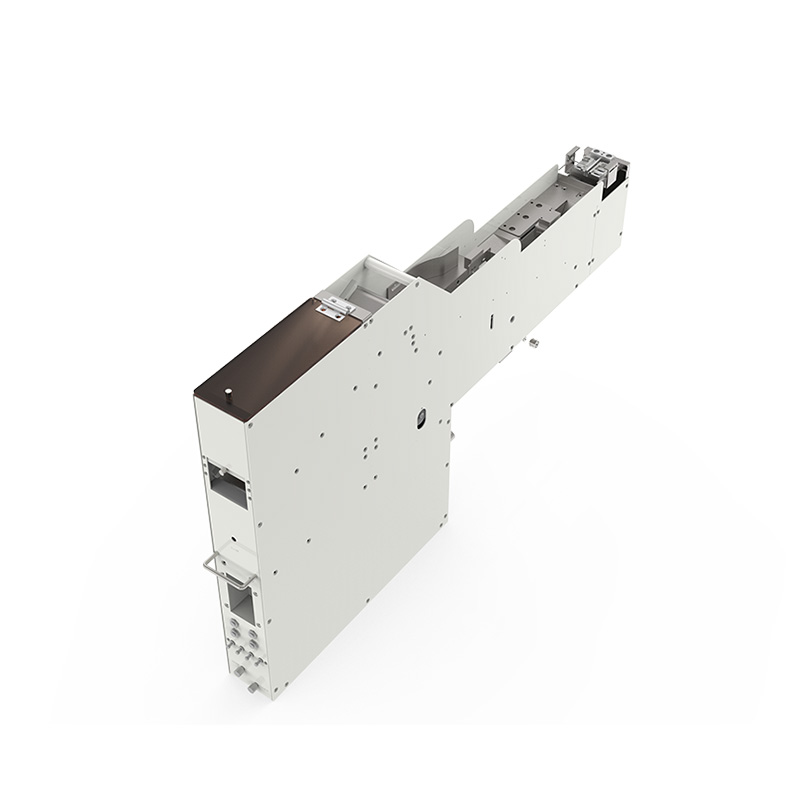

m系列创达插件机

m系列创达插件机,配置了独立的插件轴、旋转轴,具有精度更高,灵活性更强的特性,在应对复杂零件插装时,能够更加轻松的应对。为满足客户需求,接受个性化定制:包括底部弯脚、前后操作、夹头交换站、6轴&8轴、翘脚检测、超大元器件、超高元器件等功能。

m series Trand insert machine, equipped with independent insert axis, rotary axis, with the characteristics of higher precision and stronger flexibility, which can be more easily to deal with complex parts. it could be personalize customized to meet customer needs, including the bottom bent foot, front and rear operation, Nozzle changing station, 6 axis &8 axis, tilt foot detection, super large components, ultra-high components and other functions.

| M435 产品规格 Specification | ||

机器尺寸 | 1400 X 1700 X 2000mm | |

机器重量 | 1650 kg | |

操作系统 | Windows | |

开门数量 | 单边Single Side 选配双边 Double size(Optional) | |

门板安全光栅 | 标配 | |

气源*1 | 0.5-0.65 MPa (ANR) | |

设计的最大功率 | 5.4KW | |

正常运行功率*2 | 3.3KW | |

贴插轴数量 | 4 | |

贴插最大元件尺寸 | φ50 (35×35)mm | |

贴插元件高度 | ≤35mm | |

元件取料方式 | 吸嘴/ 夹爪 | |

最快贴插速度*3 / 每颗零件 | 0.7 S | |

贴插装精度(3ó) | ± 0.06mm | |

插入力量 | ≤98N | |

贴插方向 | 0-360° | |

贴插元件对象 | 各种连接器、开关按钮、变压器、端口插座、电容、电阻、集成芯片等元器件 | |

基板尺寸 | 70×70 ~ 410×500 mm | |

治具尺寸 | Max 410×500mm | |

基板厚度 | 0.6-2.0 mm | |

基板通过高度 ( 上/下) | 35 mm / 20 mm | |

基板最大重量 | 5 Kg | |

基板夹边宽度 | ≥5mm | |

基板固定方式 | 伺服顶板/气缸夹紧 Sero / Cylinder clamping | |

轨道*4 | 链条 | |

迸板方向 | 左→右 /右→左 R to L / L to R | |

轨道分段 | 3 | |

轨道调宽 | 自动 | |

轨道离地高度 | 900 ± 20mm | |

插件弯脚模组*5 | 选配 | |

激光测高 | 选配 Option | |

吸嘴交换站吸嘴交换站 | 选配 Option | |

联机信号接口 | 选配 Option | |

| MES 对接*6 MES Connection | 标配 | |

影像系统 | Mark CCD (Top) | 1 |

| Component CCD (Bottom) | 4 | |

供料器最大装载数 | 201立式编带 | 6 |

218立式编带 | ||

207立式编带折弯90 ° | ||

259立式编带 | 12 | |

254立式编带 | ||

202卧式编带 | 6 | |

222管装 | 12 | |

203管装 | 6 | |

205散料 | 4 | |

托盘供料器 | 1 | |

注:如多种类型供料器混合使用,则依实际情况确定使用数量 | ||

说明:

*1气源为大气压霜点:-17℃以下,微粒粉:粒径5μm以下,最高油分浓度:5mg/m3以下,另外机器安装时需要气源;

*2根据使用条件会发生变化;

*3视乎不同元件;

*4标准机是链条,可以定制皮带;

*5选配弯脚模组会取代顶板机构,弯脚范围请和我司相关人员索取;

*6只提供原厂设定信息. 需要配合客户系统可定制(选配项)。

Statement:

* 1 Air should be atmospheric frost point: under -17℃, Power Particles: under 5μm, The highest Oil content: under 5mg/m3 . In addition, it need air when machine setup;

* 2 Changed by the using condition;

* 3 Depends on different components;

* 4 The standard machine is chain conveyor, but it can be customized as belt;

* 5 Lead clinching unit will replace the PCB supporting mechanism;

* 6 Only provided the original data format, the rest should be customized.